The UV LED lamp function of the 126W 2 in 1 UV LED Nail Lamp and Nail Dust Collector Machine is incredibly powerful and can be used to cure almost all...

READ MOREOur Categories

- UV LED Nail Lamp

- 60UV/LED Beads Nail Dryer

- 57UV/LED Beads Nail Dryer

- 54UV/LED Beads Nail Dryer

- 48UV/LED Beads Nail Dryer

- 42UV/LED Beads Nail Dryer

- 39UV/LED Beads Nail Dryer

- 36UV/LED Beads Nail Dryer

- 33UV/LED Beads Nail Dryer

- 30UV/LED Beads Nail Dryer

- 24UV/LED Beads Nail Dryer

- 12UV/LED Beads Nail Dryer

- 6UV/LED Beads Nail Dryer

- 5UV/LED Beads Nail Dryer

- 3UV/LED Beads Nail Dryer

- Nail Dust Collector

- Nail Drill

- Multifunctional Manicure Appliance

Custom 35000RPM Nail Drill Manufacturers

-

35000RPM Coreless Handle Rechargeable Nail Drill

-

Electric 35000RPM Nail Drill Machine File Drill Set Kit

-

40W 35000RPM Rechargeable Portable Nail Drill Machine

-

40W 35000RPM Rechargeable Electric Manicure Machine Kits Tool

-

35000RPM Portable Electric Nail Drill Manicure Machine For Acrylic Gel Polish Nails Sander

-

35000RPM Manicure Electric Transformer Polishing Nail Drill

-

35000 RPM Electric Nail Drill Bits Set

About Us

Yuyao Lanqiang Electrical Appliances Co., Ltd.

ABOUT LANQIANG

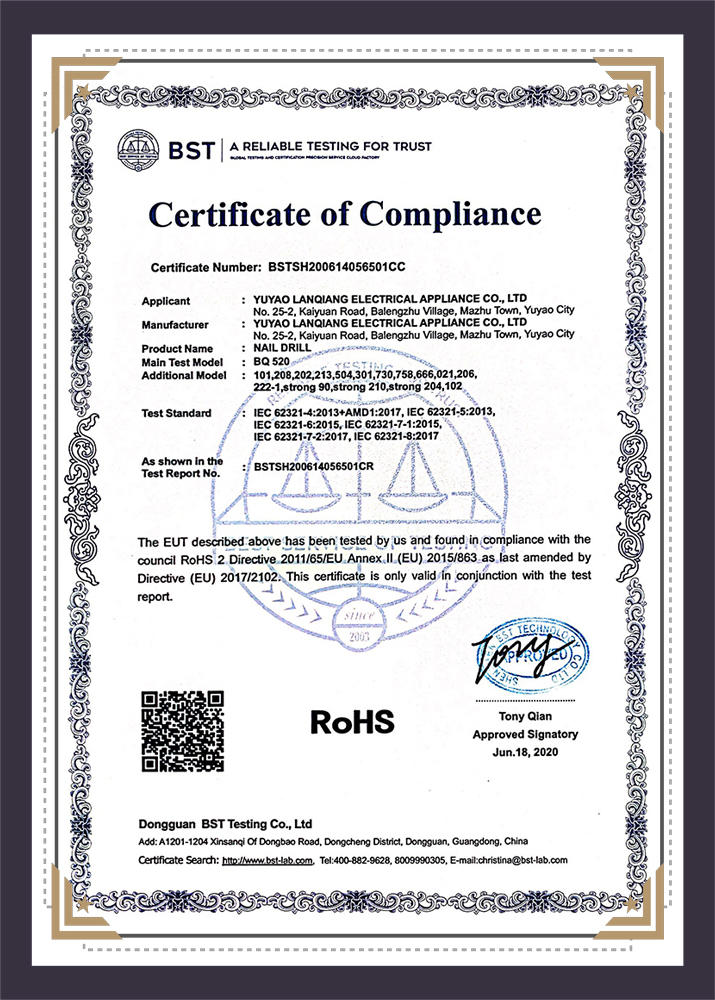

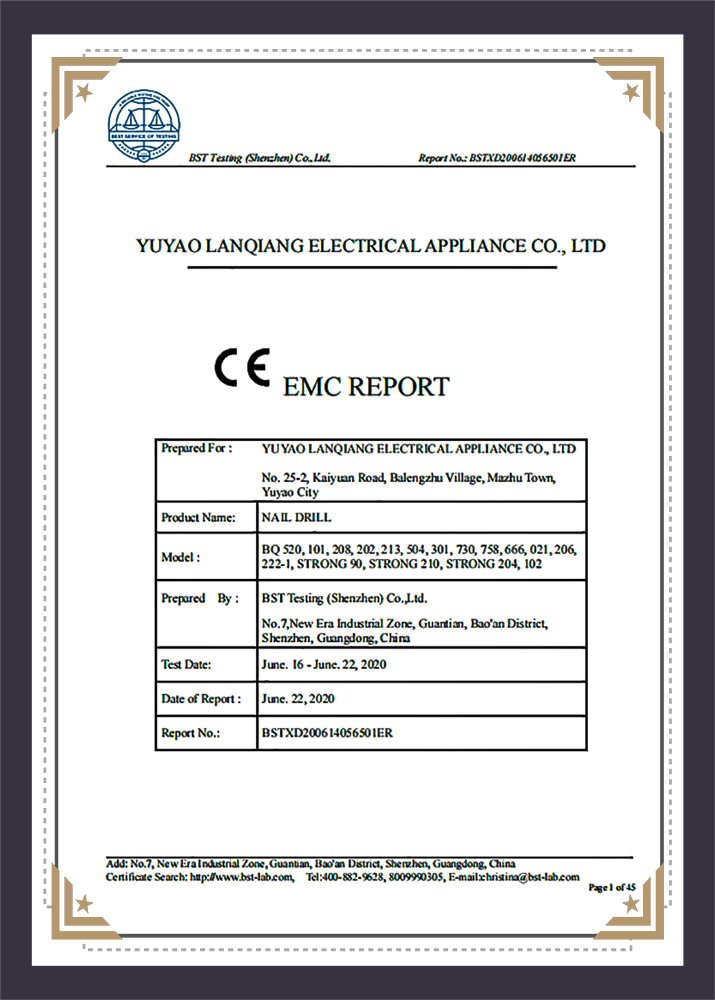

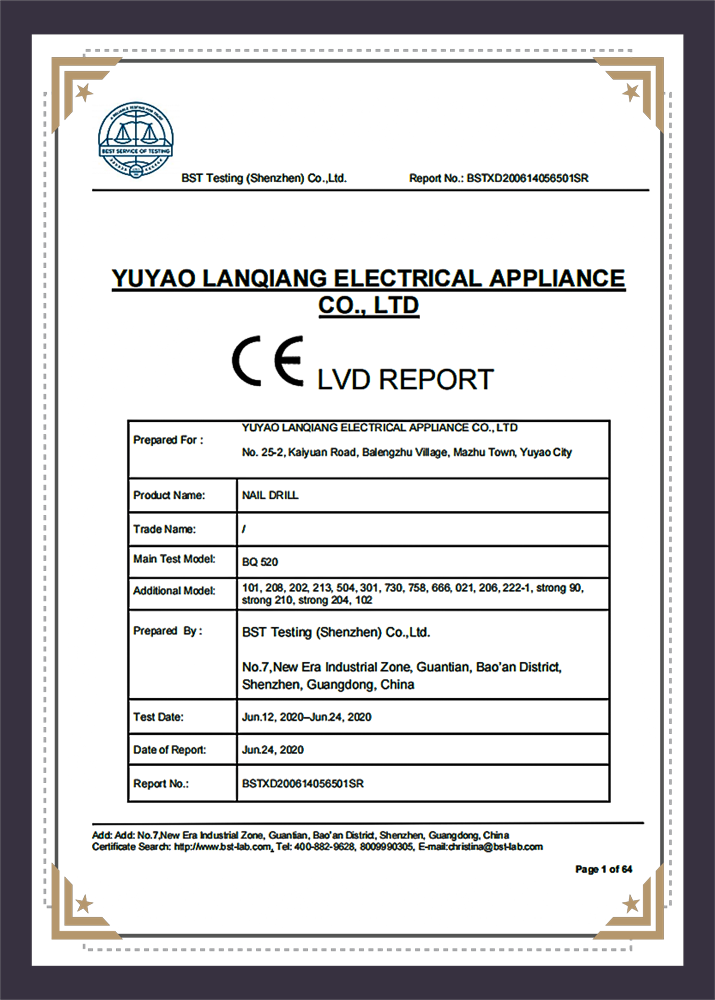

Yuyao Lanqiang Electrical Appliances Co., Ltd. is innovative China 35000RPM Nail Drill Manufacturers and Custom 35000RPM Nail Drill Suppliers, which is founded in 2010 and located in Ningbo, China. We have our own brand "BLUEQUE". We specialize in manufacturing nail lamps, nail drills, and nail dust collectors. Meanwhile, we provide OEM and ODM services for customers in the world. We have passed the ISO900l: 2015 quality management system certification and BSCI social responsibility system certification. All of our products are certified with CE, RoHS, UKCA, FCC, and relevant certifications. Our sales cover Europe, America, the Middle East, and also the Asia markets. We have an experienced R&D team, efficient manufacturing processes, professional sales teams, and strict quality control teams and we adhere to the principles of steady business, continuous innovation, and open minds. When you contract Yuyao Lanqiang Electrical Appliances Co., Ltd. you are not only our customer but also become our partner. We are a trusted and highly regarded manufacturer. We will continuously create value for our customers and the whole society.

-

-

A nail dust collector is an essential tool in the modern nail industry. It not only cleans the work area but also protects the health of nail technici...

READ MORE -

When it comes to hand care and cleanliness, an efficient and user-friendly nail dust collector is undoubtedly an indispensable tool. The 40W Nail Dust...

READ MORE -

In the fast-paced modern life, beauty and convenience always go hand in hand. For women who pursue fashion and individuality, nail art is undoubtedly ...

READ MORE

35000RPM Nail Drill: How to ensure the safety of operation at high speed?

Professional training and operating skills:Operators should receive professional training and master the correct operating skills and safety measures. The training content should include the correct use of the equipment, hand posture, operating skills, etc. Through systematic training, operators can understand how to safely use the nail drill at high speed and avoid potential dangers.

Safety protection devices:

35000RPM nail drills should be equipped with a variety of safety protection devices to ensure the safety of operation. These devices include overload protection, overheating protection and protective covers. Overload protection can automatically stop the operation when the equipment is overloaded to prevent the motor from overheating or damage; overheating protection can monitor the temperature of the equipment and automatically cut off the power when the temperature is too high to protect the safety of the equipment and the operator; and the protective cover can prevent the nail drill bit from accidentally contacting the operator's skin and reduce the occurrence of accidental injuries.

Operator self-protection awareness:

Operators should maintain a high degree of vigilance and self-protection awareness when using 35000RPM nail drills. They should pay attention to hand posture and strength control to ensure stable operation of the equipment. In addition, the operator should avoid operating the nail drill in a state of fatigue or distraction to avoid accidental injury. Regularly checking the working status and safety devices of the equipment, and timely discovering and solving potential safety hazards are also important measures to ensure operational safety.

Design and materials of the 35000RPM Nail Drill: Does it meet the professional standards of the nail industry? Ergonomic design:

The design of the 35000RPM nail drill should comply with ergonomic principles to ensure the comfort and work efficiency of the operator. The handle design of the equipment should conform to the holding habits of the human hand to avoid hand fatigue during long-term use. The layout of buttons and control panels should be reasonable to facilitate the operator to operate and adjust the equipment. In addition, the shell of the equipment should adopt an anti-slip design to ensure the stability of the operator during use. High-quality materials:The material quality of the 35000RPM nail drill is directly related to the stability and durability of the equipment. High-quality materials should have high strength, wear resistance and corrosion resistance, and be able to withstand long-term use and frequent operation. Common materials include high-quality plastics, stainless steel and aluminum alloys. In addition, key components of the equipment, such as motors and bearings, should be selected from high-quality brands to ensure the stability and durability of the equipment.

Safety and maintainability:

The design of the 35000RPM nail drill should take safety and maintainability into consideration. The equipment should be equipped with safety protection devices, such as overload protection and overheating protection, to ensure the safety of operation. In addition, the structural design of the equipment should be simple and easy to maintain, which is convenient for users to carry out daily cleaning and maintenance work and extend the service life of the equipment.

Using the 35000RPM Nail Drill for manicure services: Is professional training and skills required?

Correct operation method:The correct operation method is required to use the 35000RPM nail drill for manicure services. The operator should understand the basic operating skills such as starting and stopping the equipment, speed adjustment, and head changing operations to ensure the accuracy and safety of the operation. In addition, the operator should also learn how to perform different operations according to the needs of customers, such as trimming, grinding, carving, etc.

Safety measures and operating skills:

The operator needs to understand and comply with relevant safety measures and operating skills to ensure the safety of operation. For example, the operator should pay attention to hand posture and strength control to avoid accidental injuries under high-speed rotation. In addition, the operator should also understand the safety protection devices of the equipment, how to use and maintain them correctly to ensure the stable operation of the equipment. Nail design and customer service:

In addition to training in technical operation, operators also need to have good nail design and customer service capabilities. They should be able to carry out personalized nail design according to the needs and preferences of customers, and provide professional advice and opinions. In addition, operators should also have good communication skills and customer service awareness, fully communicate with customers, and provide high-quality nail services.

English

English Español

Español