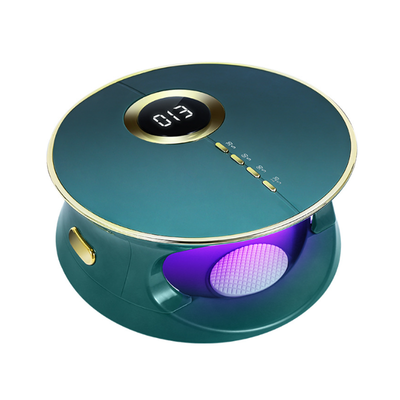

In the modern nail industry, UV LED nail lamps have become an indispensable tool, and their efficient curing ability provides strong support for the improvement of nail technology. However, correct operation and maintenance are essential to ensure the performance and safety of equipment.

Basics of safe operation

Avoid looking directly at the UV light source

Although the UV light emitted by the UV LED nail lamp is of moderate intensity, long-term direct viewing may still cause irreversible damage to the eyes. Therefore, when using the UV LED nail lamp, be sure to wear certified protective glasses to effectively block direct exposure to UV light and protect the eyes from damage.

Prevent skin exposure

The potential harm of UV light to the skin cannot be ignored. Prolonged or high-intensity UV exposure may cause skin burns or trigger photosensitivity reactions. Therefore, during operation, it is recommended to wear long-sleeved clothing and long pants, and wear gloves to ensure that the skin is not directly exposed to UV light and reduce health risks.

Pay attention to ventilation and heat dissipation

UV LED nail lamps will generate a certain amount of heat when working. If the environment is poorly ventilated, it may cause the equipment to overheat, which will affect its performance and safety. Ensure that the device is placed in a well-ventilated area to help dissipate heat effectively and prevent equipment damage or safety hazards caused by overheating.

Correct use and maintenance

Correct installation and wiring

When installing the UV LED nail lamp, ensure that the direction of the lamp is correct and the wiring is stable and reliable to avoid equipment failure caused by incorrect or loose wiring. Check the integrity of the power cord regularly. If damaged, replace it in time to ensure the safe use of the equipment.

Regular cleaning and maintenance

To maintain the optimal performance of the UV LED lamp and reflector, it is recommended to regularly use a soft dust-free cloth to gently wipe its surface to remove dust and dirt. This process not only improves the uniformity and intensity of ultraviolet radiation, but also effectively extends the service life of the lamp. It should be noted that cleaning agents containing alcohol or other corrosive ingredients should be avoided to directly contact the LED chip to prevent damage.

Control exposure time

According to the specific curing requirements of the nail glue or nail polish used, it is crucial to reasonably set the exposure time of the UV LED nail lamp. Too long exposure time may lead to over-curing, affecting the nail effect; while too short exposure time may lead to insufficient curing, affecting the durability and appearance of the nail.

Avoid frequent switching on and off Frequent switching on and off of the UV LED nail lamp will have a negative impact on its service life. Therefore, if conditions permit, the number of switching on and off should be reduced as much as possible to extend the service life of the equipment.

English

English Español

Español