Regular inspection of the appearance of the filtration system is a basic task to ensure the normal operation of the equipment. The operator needs to carefully check the filter housing to confirm whether it is damaged, stained or dusty. If there is dust on the housing, it is recommended to use a mild detergent or a clean cloth to gently wipe it to remove the dirt on the surface. However, it is necessary to avoid using too much water or liquid to avoid damaging the filter. At the same time, the smoothness of the exhaust port is also very important, because it is the connection point between the equipment and the outside world, and any blockage may affect the normal operation of the equipment. To ensure the cleanliness of the exhaust port and its surrounding areas, it is recommended to use a vacuum cleaner or a wet cloth to clean it to maintain a good exhaust state.

As a key component of the filtration system, the cleaning and replacement of the filter element must strictly follow the relevant specifications. After removing the housing, take out the filter element and gently brush the surface of the filter element with a soft brush to avoid damaging it. Then, rinse the filter element with clean water and place it in a well-ventilated environment to dry it. After drying, reinstall it. The replacement cycle of the filter element should be determined according to the specific usage and the manufacturer's recommendations. Generally, the filter element should be replaced in time for three to six months, or when the resistance value of the filter exceeds 2 to 3 times the initial resistance. During the replacement process, be sure to select a filter element that matches the equipment and avoid using filter elements of different models to ensure that the filtering effect is not affected.

Sealing inspection is also an important part of maintaining the filtration system. The sealing of the frame of the filtration system is directly related to the dust removal effect of the equipment. If the seal is not tight, it may cause dust leakage, which will not only affect the working environment, but also pose a threat to the health of the operator. Therefore, it is necessary to check the sealing of the frame regularly. If the sealing material is found to be aging or damaged, it must be replaced or repaired immediately.

In terms of equipment operation, regular inspection of the normal operation status of the power supply and control system should not be ignored. At the same time, it is recommended to regularly clean the equipment, including the filter element, housing and related components. Neutral detergents should be used for cleaning to avoid damage to the surface and internal structure of the equipment. When cleaning and maintaining, be sure to cut off the power supply first to prevent accidents. When cleaning and replacing the filter element, the operator should wear protective equipment such as gloves and masks to ensure the safety of operation.

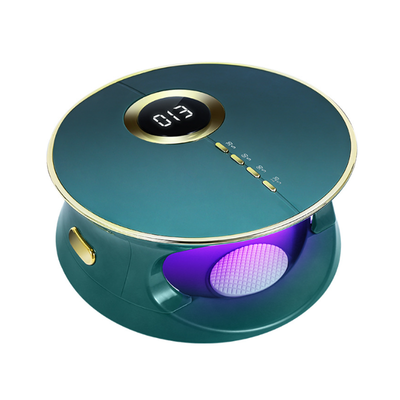

The storage environment of the equipment also has a significant impact on its performance. The Nail Vacuum Dust Collector should be stored in a dry, well-ventilated environment, away from direct sunlight and humid conditions. For filters that are not used for a long time, it is recommended to power on the machine regularly to prevent the equipment from aging. When installing and replacing filters, be sure to follow the relevant installation guidelines and precautions to ensure the correct installation and sealing.

English

English Español

Español