In the nail industry, nail lamps are a key tool. The stability and durability of their performance directly affect the quality of nail art and the work efficiency of nail artists. If the heat generated by nail lamps during operation is not effectively dissipated, it may have a series of negative effects on the equipment itself and the nail process.

Impact of heat dissipation and ventilation on the performance of nail lamps

When the nail lamp is working, the internal LED light source or UV lamp tube will release a lot of heat. If the heat cannot be dissipated in time, the internal temperature of the equipment will increase significantly, which will directly affect the luminous efficiency and stability of the light source. Long-term exposure to high temperature will not only shorten the service life of the light source, but may also cause equipment failures, such as circuit board burnout or lamp breakage. Therefore, ensuring that the nail lamp has an effective heat dissipation and ventilation mechanism is a key factor in maintaining its stable performance and extending its service life.

Impact of heat dissipation and ventilation on the nail process

The core function of the nail lamp is to fix the nail design by quickly drying nail polish and gel. However, if the equipment does not dissipate heat well, the accumulation of heat will cause the surface temperature of the lamp to be too high, which not only accelerates the curing speed of nail polish and gel, but also may cause uneven curing, thus affecting the final manicure effect. In addition, excessively high temperatures may also cause burns to the skin of manicurists and customers. Therefore, a good heat dissipation and ventilation mechanism not only helps to maintain the normal working temperature of the nail art lamp, but also ensures the comfort and safety of the manicure process.

Implementation methods of heat dissipation and ventilation

To ensure effective heat dissipation and ventilation of the nail art lamp, the following measures are usually taken:

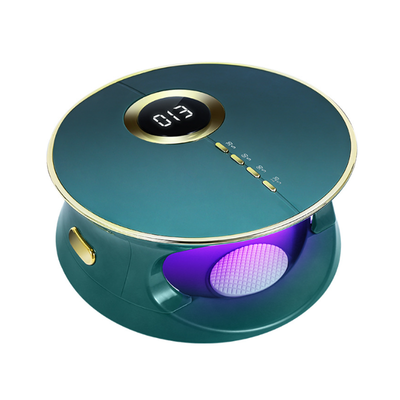

Heat dissipation hole design: There are multiple heat dissipation holes designed on the shell of the nail art lamp. These holes not only help to dissipate heat, but also ensure air circulation to prevent overheating inside the equipment.

Fan heat dissipation: Some high-end nail art lamps have built-in fans, which quickly take away the heat inside the equipment by forced convection to achieve efficient heat dissipation. This method is particularly suitable for high-power and long-running nail art lamps.

Heat dissipation material selection: Using materials with good thermal conductivity in the shell and internal structure of the nail art lamp can more effectively transfer heat from the light source to the heat dissipation holes or fans, significantly improving the heat dissipation efficiency.

Ventilation environment: When using a nail art lamp, it is important to maintain good ventilation in the surrounding environment. Avoid placing the device in a closed or narrow space to prevent heat accumulation.

English

English Español

Español