In the nail industry, the uniformity of the curing effect is directly related to the quality of the product and customer satisfaction. As a modern nail equipment, the uniformity of the light source of UV LED Nail Lamp is one of the key factors to improve the curing effect. The rationality of the light source layout determines the uniformity of light coverage. The traditional LED chip arrangement often has the problem of concentrated or uneven distribution. This design defect may lead to insufficient or excessive light in some areas, thus causing uneven curing. Therefore, the use of multi-point uniformly distributed LED array design has become an effective way to improve the uniformity of light. By accurately planning the layout of LED chips, it can be ensured that each nail area can obtain balanced light, thereby reducing the generation of shadows and light dead angles. At the same time, the selection of high-quality heat dissipation materials and structural design can effectively maintain the stable luminous efficiency of LED chips during operation and prevent the unstable light intensity caused by temperature increase.

The wavelength and light intensity control of the light source are also the core elements to ensure the uniformity of curing. Different types of gel materials have different wavelength sensitivities to ultraviolet light. Choosing the appropriate wavelength range can ensure that the light energy is evenly distributed on the entire nail surface. Some high-end UV LED Nail Lamps are equipped with multi-wavelength and multi-color light sources, which can adjust the spectrum according to the needs of different materials, thereby improving the uniformity and effect of curing. In addition, the light intensity adjustment function enables manicurists to flexibly adjust the output power according to actual conditions, avoiding the problem of insufficient curing due to insufficient light intensity or local over-curing due to excessive light intensity.

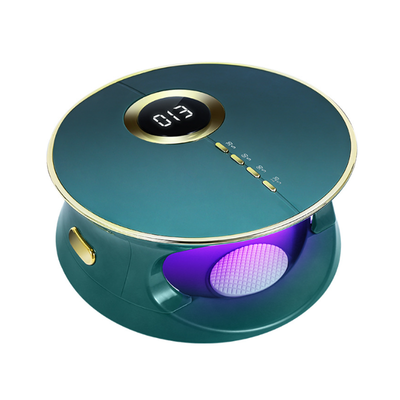

The structural design of the equipment is also an important factor affecting the uniformity of curing. Reasonable optical design can effectively disperse light and reduce the concentration and deviation of light. For example, using reflectors or diffuse reflective materials to cover the internal optical path can evenly reflect light to every corner of the nail to ensure the uniformity of light distribution. The optical structure inside the equipment should minimize the loss and deviation of light, thereby improving the overall irradiation effect. Some advanced UV LED Nail Lamps are also equipped with multi-angle and multi-directional light-emitting designs to adapt to nails of different shapes and sizes, ensuring that every part can be fully cured.

In actual operation, it is crucial to ensure that the nail maintains the correct position and posture during the curing process. Manicurists should ensure that the nail is completely in the center of the illuminated area to avoid insufficient curing at the edges or corners due to deviation from the light source. For devices that cure multiple fingers at the same time, it is important to ensure that each fingertip receives light evenly to avoid under- or over-curing of some fingertips. In addition, proper control of curing time is also a key factor in ensuring uniform curing. Different gel materials and device models may require different curing times. Too short a curing time will result in incomplete curing, while too long a time may cause over-curing and discoloration.

English

English Español

Español